Are you confused among the impact ones or the regular ones, right?

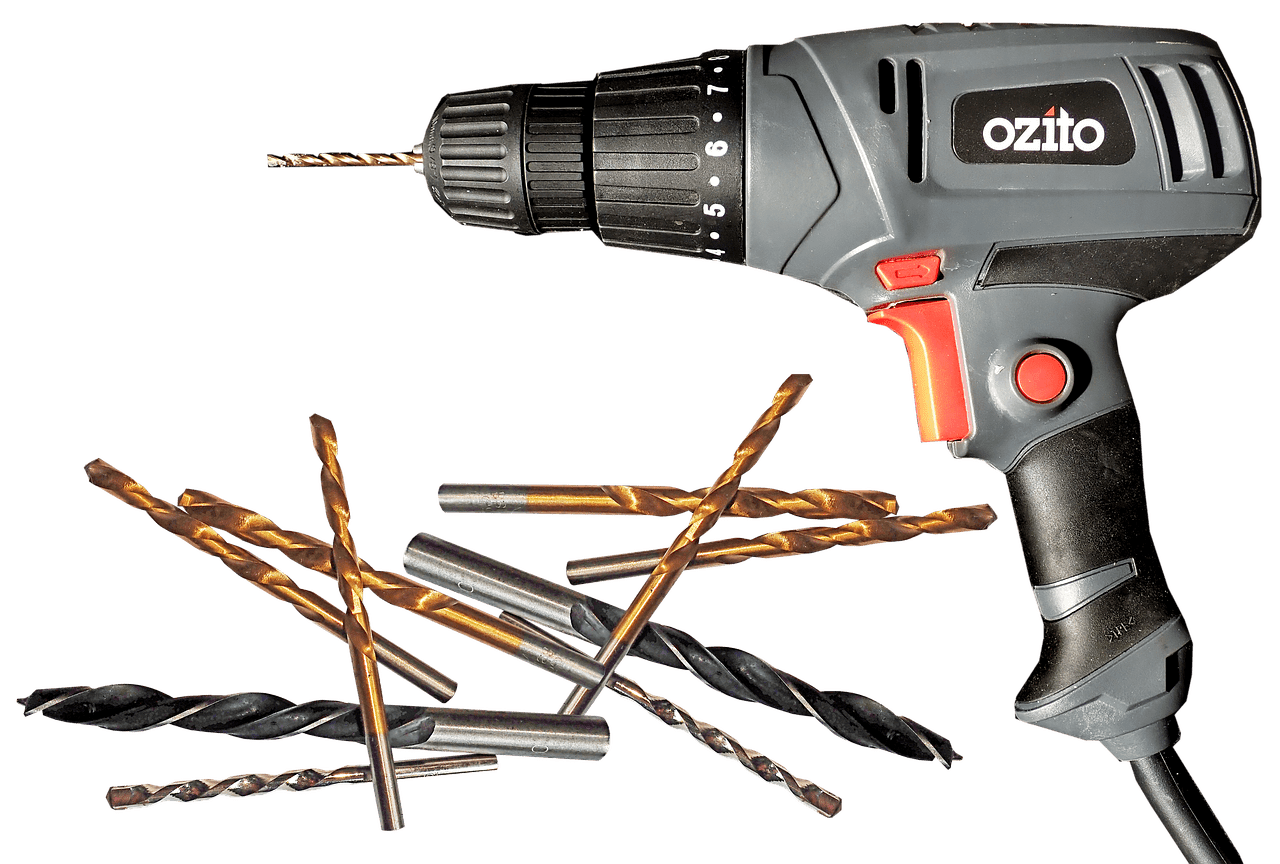

There are several types of bits in the market. Some are for woods, and some are for metals.

Also, some of them are regular drill bits and some of them are impact drill bits.

As you have reached this article I am sure you want to know about the bits.

Well, this is why I am here. I have researched for hours, days and came up with the differences among these two types of drill bits.

Let me tell you first, the purpose is not to find a winner among these two types of drill bits, rather you will have a full idea about their differences.

Knowing these differences will help you to pick up the best suit bit for your project.

But before buying any of the drill bits you have to have the drivers as per their category. I mean, yes! The drills are also different.

You will need an impact driver for impact bits and a regular drill for the regular bits.

Ok then, let's do the first thing first.

Let's know about the drill first. A short idea about them will help you get a clear idea about the bits as well.

No more introductory talking. The direct discussion starts now.

You Might also Want To Know:

Difference between a drill and an impact driver

There are a really small number of tools which are as versatile as a drill. It is capable of making holes in woods, metals, concrete etc.

You will be able to make any screws go into the surface or pull it out from it.

Drill drivers:

Drill drivers are hole makers and they are the fastener for screws, nuts, and bolts.

It has a clutch which allows you to divert the motion of the driver. You can use this machine anytime anywhere when you need to make a hole.

It is a perfect fit for your DIY projects.

Impact drivers:

Impact drivers on the other hand are made for professional home working. The professional homeworkers are fond of these types of tools.

The hex-shank bits are designed for this driver type. There are also some other types of shanks.

These tools are lighter and smaller than drill drivers. They will do the same work as the drill drivers but with a heavy impact and fast result.

The difference:

The key difference among these drivers is power and rational difference.

The impact drivers have the function of accepting all types of hex-shanked bits which the drill drivers lack.

The impact drivers are so powerful that you will be able to drive the largest nuts or screws with ease.

The impact drivers are named after their impact and force.

They produce more torque than the drill bits which enables you to deal with the screws more effectively.

Here we are done with the drills, now let's focus on our target. It is the bits.

You have heard about the hex-shanked based bits here. We are going to discuss the difference in detail now.

Impact Driver Bits VS Regular Bits

Now, we are back in business. Lets waste less words and time. Directly move to the next section for a battle among the Impact driver bits and the regular bits.

1. General differences ( what are they?):

I have tried to make the differences on the topic and right to the point.

I do not want to waste your time by exaggerating.

These are the common typical and manufacturing differences are listed in this section

I have started with what they are. This will give you an initial idea and their difference. Then the manufacturing differences will polish the idea more. Have a look.

What is an impact driver bit?

It is a common question among the beginners. They confuse both the driver bits and the regular bits as the same.

Hell no! They are not.

A driver bit is a strong and durable bit which you use to drill into hard surfaces.

The impact driver applies more torque on the surface by dint of the bits.

It drives the torque from the machine to the surface of the metal or wood or whatever you are working with.

The Impact driver bits are generally hex-shanked bits which easily fit into the driver.

What is a regular bit?

Regular drill bits are the ones which are the common ones that you will find easily in the market.

There are different types of drill bits in the market depending on their purpose, durability and function.

Their specific design and purpose make them of limited use and they are not for professional household works.

The excess pressure of this bit can do maximum damage to your drill and surface.

Manufacturing quality:

The durability, flexibility and functional abilities of the bits are the indicators of their manufacturing differences.

The impacts bits are well built with solid hard materials and they are also coated with strong metals.

This gives the user a great outcome and ease of using them. You will get the desired hole or the screw driven in the hole as you wanted.

On the other hand, the regular bits based on their selective surface differ in case of durability.

Some of them are made for wood, some are made for plastic, some are for metals. Their durability differs based on their manufacturing quality and work purpose.

2. Functional differences:

Here in this category of differences, I have tried to talk about their differences while using.

Their relation of their structure and manufacturing with their functioning. I hope your knowledge will get more specific and clear after this.

Stress area:

You will be able to find this structural difference between the drivers by your eyes.

The regular bits have a concentrated stress area where the impact bits have an increased one.

This stress area allows them to transfer the torque into the surface or the screws that you are working on.

The more the stress area the more the impact.

Strength:

Some people consider the impact driver bits as pretty coatings.

Well, they are more than that.

The two main advantages that the impact driver bits have over the regular bits are

- Great torshional length

- Larger breaking angle

These two functions provide you with flexibility and longevity of the bits. The shape of the shank and the special built tip shifts the stress from the tip of the bit into the surface.

On the other hand, the regular bits are not capable of handling such pressure or torque.

As a result, they might break down.

The winner?

Well, it is a tough decision to be made.

I have said before that the purpose of this article is not to find a winner, rather I want to show you the difference among them.

The reason behind it is that both of the bits are made for the same purpose.

It is to drill or drive.

Both of them are capable of doing it very well.

The difference lies in their torque and impact and torsion.

The regular bits lack those qualities a little less. You have to use a regular bit either to drill wood or plastic or metals.

On the other hand, the impact driver bits are capable of doing them all. They are the “John Cena” of drilling.

On the other hand, the suggestion is that you have to keep in mind if you are an enthusiast or a professional worker. You will not be needing the impacting driver bits if you are in a DIY project.

You also have to keep in mind which type of driver you are using. You have to purchase the bits depending on your machine type as well.

Conclusion

So, I do not want to give any final decision about any of the bits.

They are built according to their needs, purpose and they are doing well in their fields.

You are the one who has the right to make decisions.

Decide as per your project type, your project needs and reach to a conclusion which one you want to have in your toolbox.